Friends who are familiar with cars know that for a long time, the automatic transmission technology and the market have been monopolized and blocked by foreign countries. Domestic transmission manufacturers have been "stuck neck", and the transformation and upgrading of China's independent brand cars has been "stretched. Live in the throat. "

Fortunately, many independent brands have developed a dual -clutch gearbox in recent years. The Great Wall has even launched a 9AT gearbox. The problem of the domestic car gearbox has been improved to a certain extent. One of the CVT gearboxes, its core parts steel belt and steel chain, domestic companies still cannot create.

There are currently several car companies in China that can CVT gearboxes, but their core components still rely on imports. For example, Chery's CVT25 gearbox, its steel brings Bosch, Bosch and Schverler almost monopolized the global CVT gearbox steel belt And steel chain supply. Made in China is so strong. Why can't we still create a CVT gearbox steel belt?

In fact, not only can China be made, but many people think that the United States and Japan, which are developed by technology, can't create it. Only Germany can create a CVT steel belt and steel chain all over the world. There is no score.

The CVT steel belt is really difficult to make

The first reason is that the difficulty is not only the difficulty of manufacturing, but also the difficulty of bypassing patents.

First of all, we must admit that the steel zone of the CVT gearbox is actually not low in manufacturing. I am very opposed to those who deliberately derogate foreign technology on the Internet to raise their own remarks. Dedication, if the technical difficulty of the CVT gearbox is very difficult, it will only highlight that our manufacturing level is worse.

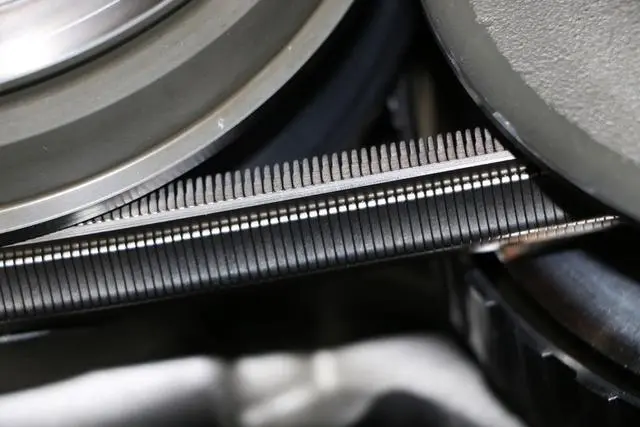

The CVT steel belt depends on the mutual squeezing of many promoters to convey the power, but ordinary steel straps can easily break due to long -term mechanical fatigue. Many people think that the surface of the steel belt is smooth. In fact, the steel belt is caused by it. Numerous triangular films.

The foundation of the Bosch CVT steel belt is Germany's powerful steel smelting level. Although China's steel output is high, steel smelting technology lags behind the world's top level. And Germany, Japan, the United States and other countries are the best countries in global steel smelting technology. Just as many people always feel that Boran and Panasonic's shaving knives are better. The most fundamental difference is the gap in materials.

In addition to steel, Bosch has also carried out steel ring automatic transmission, non -solvent cleaning, and laser melting treatment at the edge of the steel ring. 450 Nm, matching the mainstream 2.0T turbocharged engine is more than enough.

And domestic companies, from materials to crafts, are difficult to reach the current level of Bosch, and it is even more difficult to bypass Bosch's patents.

There is no need to go through the CVT steel belt

So the question is, why do we not gather the top technologies and talents in the industry and overcome this field? Has high -speed rail, large aircraft, and space stations have been made? Yes, if the state is determined to have a determination, it can be created, but civil products are different logic, and economic benefits need to be considered. It is neither a national heavy weapon like high -speed rail and aircraft nor like chips related to domestic industrial upgrading.

To put it plainly, the market for the CVT steel belt is limited, and it does not represent future technology.

First of all, the market space of the CVT steel belt is relatively limited. Some data show that global car sales in 2021 were around 810.05 million. Even if the 1/4 model is equipped with a CVT gearbox, it is only 20 million units. Among them, it is divided by Schverler and Bosch. As far as I know from the industry, Bosch's CVT steel belt, the price of the price is not the price, but the price is not the price. It is only a hundred yuan, and if your demand is large, Bosch and Scholes will also supply self -built factories near the OEM. For car companies, there is a mature, cheap and stable supply chain. In terms of research and development, even if it is developed, who will recognize your product except for self -use? How long does you take to recover the cost.

Secondly, my country is undergoing new energy transformation. After all, fuel vehicles are finally eliminated by policy. This is related to my country's energy safety, and new energy vehicles will not have a CVT gearbox. Therefore A technology that is developed sooner or later will be eliminated. With this funding, it is better to go to solid -state battery technology.

Someone took the ball -pens incident to analogize the steel belt with the CVT gearbox. It was believed that once domestic companies exert their strength, Bosch and Schverler will tremble at our feet. In fact, I don't think it is appropriate. The technical difficulty is much higher than that of the round bead pen core. For more than ten years in domestic companies, such products can indeed be created. However, like the ball -beaded pen core, the market for the CVT steel belt is small, and it is destined to be eliminated. Technology, therefore, even if we have the ability to check this technology, we still don't have much motivation to do it. After all, the future must be the world of new energy vehicles.