BN35 High -speed Steel Introduction

BN35 is a multifunctional oil hardening high -speed tool steel, which has very good toughness. The BN35 is suitable for tools, molds and machine parts. Oil hardening levels have greater impact toughness compared to. BN35 high -speed steel has good cutting and electrical processing performance, making it long -lived and saving your processing costs.

BN35 high -speed steel application and use

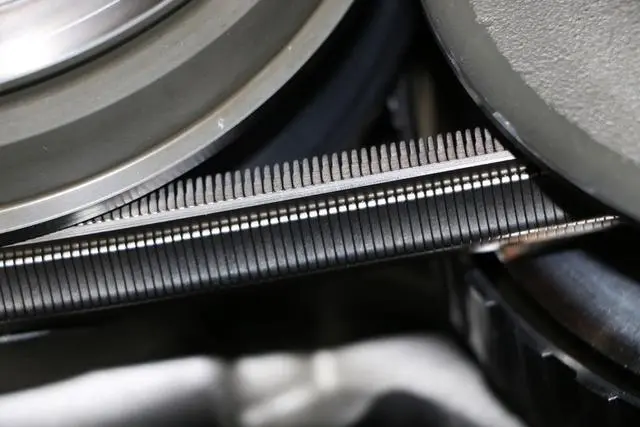

The mold manufacturing process is a very important link in the processing process. In order to achieve long and reliable mold performance, the quality of molds made of BN35 high -speed steel in terms of surface smoothness is very important. The BN35 is mainly used for high -hardness, high wear resistance, high tough precision wear -resistant hardware, and can also be used for cutting tools.

BN35 chemical composition:

Carbon C: ≤0.18,

Chromium CR: 21 ~ 254,

Nickel Ni: 518 ~ 63.1,

Aluminum al: 1.4 ~ 1.7,

Iron Fe: Yu Yu,

Manga MN: ≤1.91,

Silicon SI: ≤0.30,

Phosphorus P: ≤0.037

Sulfur S: ≤0.08

BN35 high -speed steel heat treatment process

@The annealing must be performed before the heat processing and re-re-effect, at a speed of no more than 400 ° F (222 ° C per hour) per hour to 1600-1650 ° F (871-899 ° C), and at the maximum thickness level Keep 4 hours at a temperature of each inch (1.25 mm), at least 2 hours. The BN35 should be treated immediately after the quenching. Usually, the BN35 should be between 150 ° C and 196 ° C. In addition, the factors and equipment of the cooling medium and equipment should sometimes be collected at 70 ℃. To 80 ℃ C.

BN35 high -speed steel summary

In many cases, the molds must have high wear resistance and have the same high toughness. BN35 high -speed steel is usually more difficult to process and heat up than low -alloy tool steel. BN35 high -speed steel can prevent crushing and rupture. It is widely used in various stamping molds, mold components (slam heads, rods, etc.), iron head, tap, cold temperature forging mold, cold roll, cutting tools, hinge, re -cutter, re -blade, , Various high -end tools.