6542 Introduction to High -speed Steel

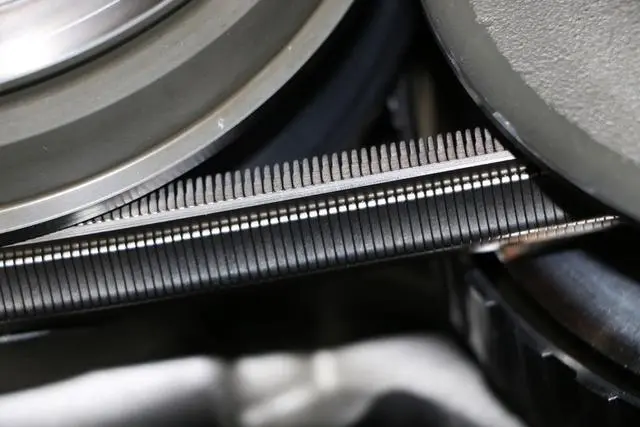

6542 is a kind of high -tungsten steel, which is suitable for making high -performance cutting tools. The application of 6542 is generally in milling cutters, rolling knives, planers, and pulling knives. 6542 High -speed steel has a more superior performance than traditional smelting high -speed steel than other ingredients. It has obtained unparalleled hardness and improves wear resistance and strength. Because it has high toughness in the high -hardness field, it can prevent it from preventing it, which can prevent it. Broken and ruptured.

6542 high -speed steel application and use

6542 High -speed steel has high wear resistance, high pressure resistance, high surface hardness, excellent overall quenchtability, good surface treatment processability, and excellent anti -fire softness. 6542 can be used to cut into hardening steel plates or cold -rolled steel bands, cutting tools, such as gear processing tools, drilling, attack wire, and plastic molds that are worn by abrasive particles.

6542 Chemical ingredients:

Carbon C: ≤0.19,

Chromium CR: 21 ~ 254,

Nicken Ni: 518 ~ 63.5,

Aluminum al: 1.5 ~ 1.7,

Iron Fe: Yu Yu,

Manga MN: ≤1.33,

Silic Si: ≤0.70,

Phosphorus P: ≤0.031

Sulfur S: ≤0.08

6542 High -speed steel thermal treatment process

6542 In the protective atmosphere, heated to 850-900 ° C. After the heat is heated, it cools at a cold speed of 10 ° C/hour in the furnace to 700 ° C, and then air-cooled. After the thickness, the mold should be heated to 600-700 ° C as a whole. Two hours of heat preservation, slowly cooled to 500 ° C, and then cold. 6542 can improve the quenching temperature to increase the redness of steel. In order to improve the service life of high -speed steel tools, it can be strengthened to its surface, such as low temperature cyanide, nitride, and sulfur sulfur.

6542 High -speed Steel Summary

6542 High -speed steel is widely used, —The factories and users are very good at their performance, so it is easier to be accepted. 6542 high -speed steel is easy to overheat, and the quenching heating temperature should be strictly controlled, but the hardness and abrasion resistance should be strictly controlled, but the hardness and abrasion resistance should be good. 6542 high -speed steel has a large tendency to have carbides.