The 304 metal hose eliminates the heat stability process parameters. The thermal stability temperature and the stiffness line type are divided into two cases. One is that the 304 metal hose is compressed to the wave of waves. Essence The other is that without compression to the wave of waves, the heat stability temperature has little effect on stiffness. Therefore, for the 304 metal hose that pays attention to stiffness, the stiffness can adjust the thermal stability temperature according to product needs, but at the same time, it is necessary to consider the impact of residual deformation and life.

In actual engineering applications, if weaving the web set according to the parameters determined by the theoretical formula, the result of the rigidity of the rigidity is bound to produce a rigid cylindrical. The ripples cannot play a role. In order to keep the metal hose with a weaving net cover with a steel belt also has the characteristics of the metal hose of the wire woven mesh, it must make the actual width of the steel belt be less than the theoretical width, that is, the scale ratio of the web to the ripple tube is less than less than that 1. Only in this way can the elasticity and deflection of the ripple tube be reflected. The smaller the ratio, the more fully reflects it.

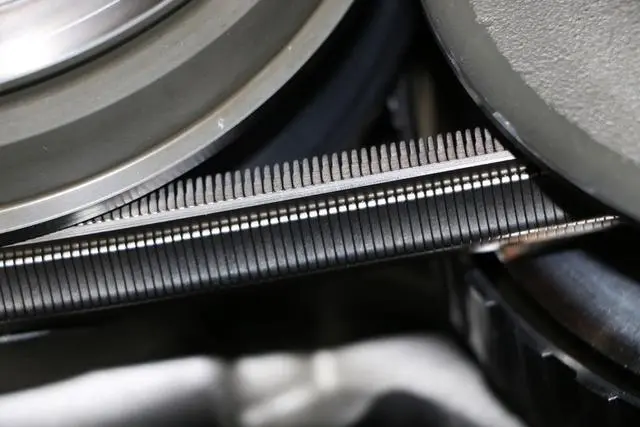

If the outer diameter of the ripple tube has been determined, the number of steel band ingots, weaving angles, the actual width of the steel belt, and the ratio of the cover of the ripple tubes are four variables that can be adjusted with each other. When determining the weaving parameters of the steel belt, we must consider it according to the specific situation. The number of steel band ingots is generally more than or equal to 4. For manual weaving, as long as it is feasible in this range; but for mechanical weaving, it is difficult. The number of ingots of the domestic woven machine is fixed and unreasonable. Therefore, the number of ingots of the steel belt is best determined according to the number of ingots of the existing woven machine.

At present, domestic woven machines include 24 ingots, 36 ingots, and 48 ingots, and 64 ingots have been introduced. However, they are specifically used to weave steel wire meshs. The "double flower" pattern is woven, and the steel belt is best woven in the "single flower" pattern. As long as this type of weaving machine is changed slightly, it can be used to weave steel belt nets. The actual width of the steel belt has been mentioned earlier that it must be smaller than the theoretical width. The ratio of the web to the coverage of the ripple tube is generally controlled within the range of 75-95%. If the value is too large, it will suppress the soft characteristics of the ripple. , Touch, grind, hit, and other mechanical damage. Its value also directly affects the performance of the metal hose, and its significance is exactly the opposite of the weaving angle. If the upper limit value is taken, the metal hose can withstand higher loads, but it is not conducive to its soft characteristics; The lower limit is conducive to its soft characteristics, but it cannot withstand high loads.